|

How to drop the

F-16’s

Flaperons

by Ryan Fernandez

HyperScale is proudly supported by Squadron

I recently read a fellow HyperScaler’s comment about all the awesome

photos of built and almost completed models being posted on Plastic

Pix but one comment he said really stood out for me. The modeler had

requested other modelers out in cyberspace to write up some how-to

techniques to help the beginners out. Well, I welcomed the request

and decided to do one: How about dropping the flaperons (combination

of aileron and flaps) on the F-16 Fighting Falcon! In my how-to

article, I am using a 1/48 Hasegawa F-16 kit and showing you how to

do this simple modification to add some extra realism to your kit!

Before I begin I want to note that in addition to the 1/48 Hasegawa

F-16 wing parts used in my article, I will be using wing parts from

another Hasegawa kit of a Japanese F-16 derivative, the Mitsubishi

F-2A. I used the wing parts of this kit as a comparison with my

dropped F-16 flaperons because the area of concern is so similar

between the two kits (albeit different wing and flaperon sizes) and

it helps to show the reader what result I am eventually trying to

get to! In other words, the Mitsubishi F-2 kit already has dropped

flaperons (as well as dropped leading edge slats) and I’m just

trying to copy “the look” by using the F-16 kit. Got it? So here

goes…

Materials needed:

1. sharp, new X-Acto No.11 blade

2. round needle file

3. Evergreen half-round plastic rod or equivalent

4. contour putty (Testor’s plastic putty or Squadron putty or

equivalent)

5. plastic cement

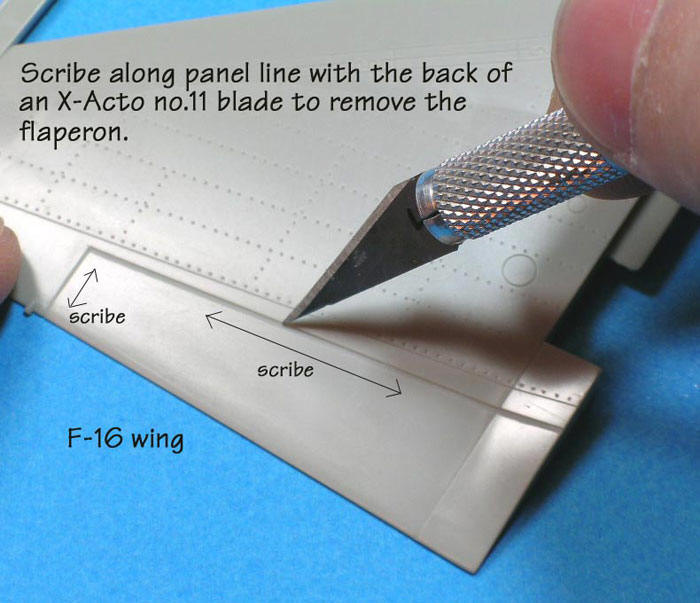

Step 1 Removing the Flaps:

To drop the flaperons (I will now refer to these parts here as

“flaps” from now on so as to avoid more typing!) on the F-16, you

will first need to cut out the parts from the main wing. Do this by

scribing along the flap’s “panel line” with the back of a sharp, new

Number 11 X-Acto blade (see fig.2). Work slowly and carefully to

avoid damaging the surrounding area of the flaps. Once you’ve

removed the flap continue to the next step.

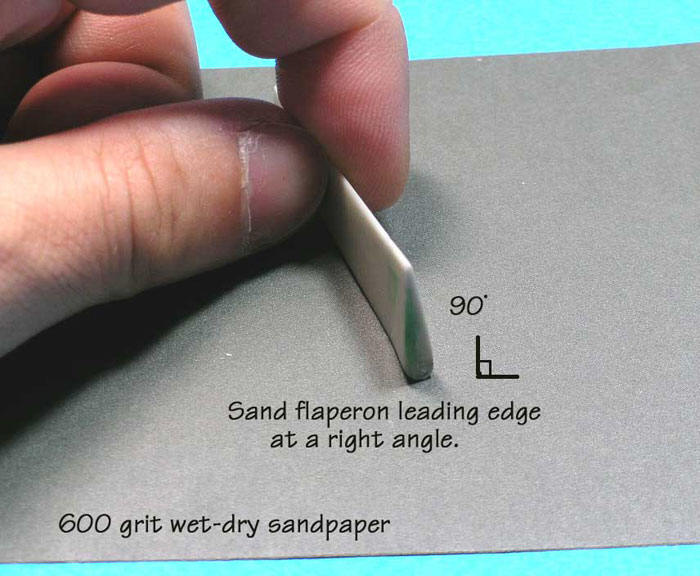

Step 2:

This part involves cleaning up and reshaping the

flap(s) you just cut off (You did remove both? No? What? Go repeat

Step 1 and cut out the other flap!). Okay class, keep up the pace

and pay attention! That means you Craig in Daytona and Wookie in the

back row! Where were we? Oh yeah…Step 2. Clean up the forward end

(the leading edge) of the flap you just cut off by sanding a little

of it flat. I use sandpaper (600 grit) placed on a flat surface

(rough side up Craig!) to accomplish this.

Why? Because it helps when you go to the next step!

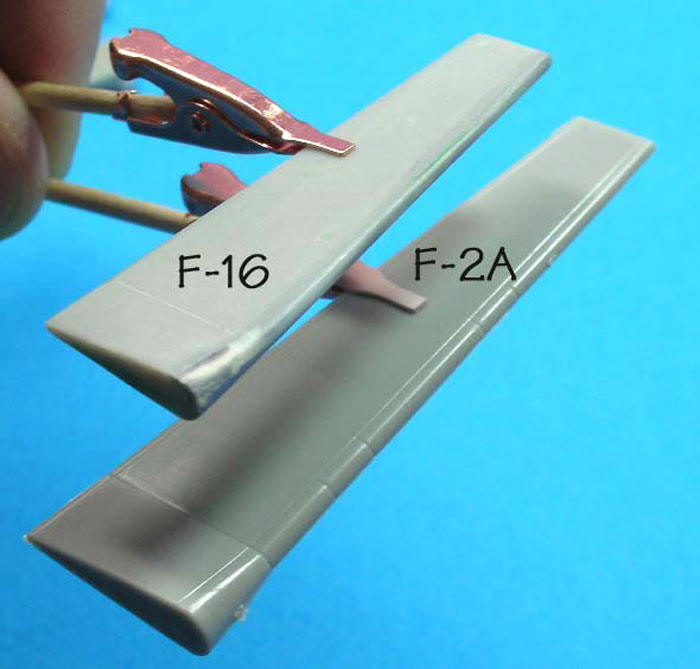

Step 3: Reshaping the flap to an aerofoil:

Next, you will need to reshape the leading edge of

the flap into an aerofoil. As molded on the Hasegawa F-16 kit, the

flaps you removed are not in the shape of an aerofoil and are a bit

short in chord. The flap needs to look like the Mitsubishi F-2A flap

(See figures 5 to 9 below and compare.) Note that the F-2A has a

bigger wing and hence a bigger flap so don’t think that the F-16

part is too small. I’m just using the F-2A parts as reference. To

get the F-16 flap’s leading edge to look like the F-2A flap’s

leading edge, you will need to glue a piece of half-round plastic

stock (available from Evergreen Scale Models, Inc.) cut to size to

match the length of the F-16 flap leading edge. Now here’s the

tricky part! Adding the half-round plastic doesn’t instantly make

the flap into an aerofoil shape. It will need some help with your

favorite contour putty (I use Testor’s plastic putty and Squadron

Green Putty) and some more sanding! Once you’ve got an aerofoil

shape, you can move on to the next step!

Click the thumbnails

below to view larger images:

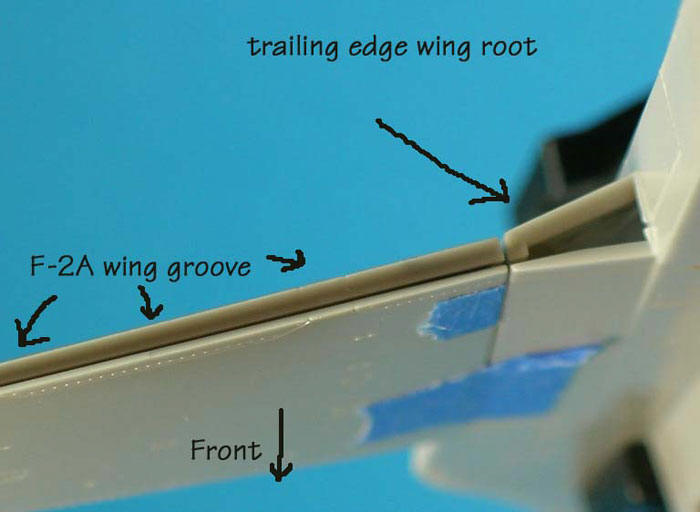

Step 4: Main wing flap well:

In this final step, you will notice that the F-2A

wing’s trailing edge has a rounded groove (trough) that exactly fits

its flap’s leading edge. On the F-16 kit wing, once you’ve removed

the flap, all you’ve got is hopefully a flat sided area that needs

some re-shaping. You were careful removing the flaps in step 1

right? To make a similar groove in the F-16’s trailing edge I used a

rounded needle file and slowly gouged the plastic until I got it in

the shape of the F-2A’s flap groove. Once you’ve reshaped the F-16’s

wing grooves to match the F-2A’s in the photo, check the fit of the

F-16 flaps to the main wings to insure a close fit. If not, more

reshaping of either the flaps or wing grooves with putty or the

needle file is required. Once you’re satisfied, you now have dropped

flaps! (Check your references to see how much to drop the flaps.)

Click the thumbnails

below to view larger images:

References

Model,

Images and Article Copyright © 2006 by

Ryan Fernandez

Page Created 05 January, 2006

Last updated

04 January 2006

Back to HyperScale Main

Page

Back to Features

Page

|

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search