|

WWI Biplane

Aligning and Rigging

Rodenís 1/72 Scale S.E.5a

by Glen Porter

|

|

|

Rodenís 1/72 Scale S.E.5a |

images by Brett Green

Roden's 1/72 scale

S.E.5a is available online from Squadron.com

The purpose of this article is not to provide a construction report

on an entire kit, but to detail one of the possible ways to align and

fit the top wing, and to rig a WWI biplane.

The subject model is Rodenís 1/72 scale S.E.5a.

Aligning the Top

Wing of a British WWI Biplane

|

After building two of Rodenís kits and encountering problems with the

alignment of the top wing, I was determined not to start another biplane

until I had worked out a better method of assembly.

One factor contributing to the problem was that both earlier projects

had twin-bay wings. This meant that I had to deal with 8 inter-wing

struts and 4 cabanes. In my haste, I tried to install them all at once.

I would have needed a few more hands to do this!

Although the final results were acceptable, especially for first

efforts, there was no way I was going to try and rig them.

Top Wing Alignment Jig

After discussing the issue with a few excellent WWI modellers and

getting a different opinion from each, I decided that I needed a jig.

The only problem was that I had absolutely no idea how to build such a

jig, and was therefore no closer to finishing my stack of unbuilt

biplanes.

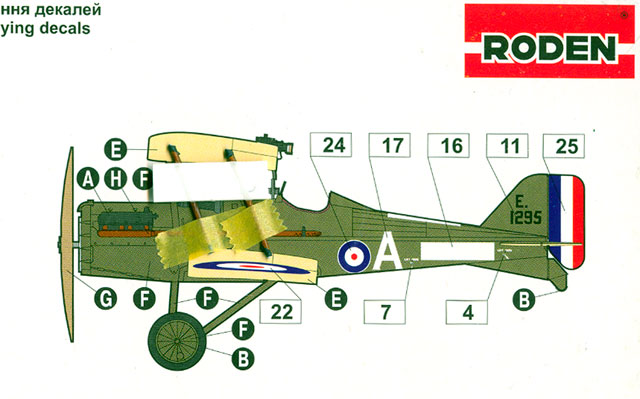

The penny dropped when I bought the Roden 1/72 scale S.E.5a biplane. I

noticed that the artwork on the back cover was drawn to a constant 1/72

scale. I figured that if I taped the two interplane struts to the

artwork and temporarily glued a piece of styrene across the struts, then

the correct angle and stagger would be set. The only remaining challenge

would be to ensure that the struts were vertical when secured to the

wings.

Of course, this solution assumed that the artwork was 100% correct, and

that any one of 100 other possible mishaps would not interfere.

Click the thumbnails below

to view larger images:

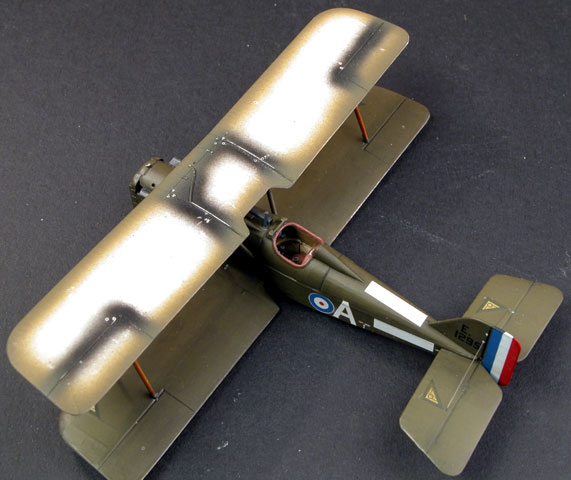

As it turns out, the plan worked well.

Fairly well anyway. I did not quite get the stagger

correct, and this resulted in the top wing being positioned too far

forward and slightly low. It is not too noticeable though, because the

slight discrepancy is the same for the entire length of the upper wing.

I consider the experiment is a success.

Tips and Pitfalls of Top Wing Alignment

Here is a short list of additional tips and possible pitfalls that

are helpful to keep in mind:

-

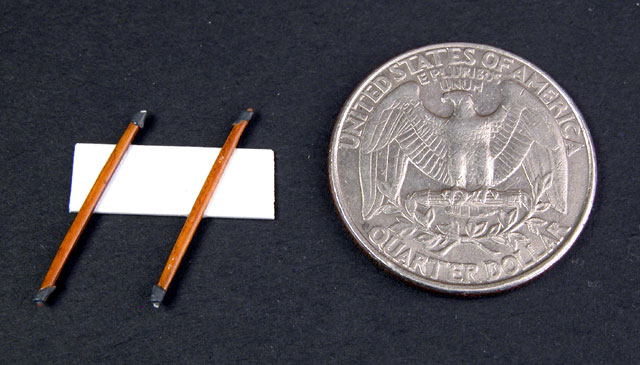

First, make sure that all of the interplane

struts are the same length. Do not assume that they are. If they are

not, it will throw the angle of the stagger out.

-

Also, be very careful when taping the

struts to the artwork as this will again effect the alignment on the

finished model.

-

Measure the distance between the mounting

holes on the wing to make sure that it conforms with the box art and the

position of the locating pins on the ends of the struts.

This procedure only applies to British biplanes or those with

individual struts. Some German biplanes such as the Fokker D.VII and

Pfalz D.XIII have ďNĒ shaped interplane struts which are simpler to

install. The Albatros D.V, on the other hand, has vee struts and you

will have to work out another method to accurately align these.

Finally, not all of Rodenís kits have 1/72 scale artwork on the back of

the box. Under these circumstances you will need to source accurate

scale drawings from elsewhere.

For a number of years now I have looked upon the task of rigging

biplanes with horror. It was enough trouble actually building the kits

without subjecting myself to further potential for trouble at the very

end of the project.

However, I was feeling ambitious after successfully implementing my

top-wing solution, so I decided to have a go at rigging my 1/72 scale

Roden S.E.5a too.

What a big difference a little bit of rigging makes!

There are many different ways to rig a biplane, and many rigging

materials available. If you have arthritic hands (as I do) you may not

even want to try it but, believe me, the results are worthwhile. Without

rigging, my S.E.5a looked like a toy. With rigging it looked, well, a bit

less like a toy! You can make up your own mind by looking at Brettís

photos of my model.

The Rigging Process

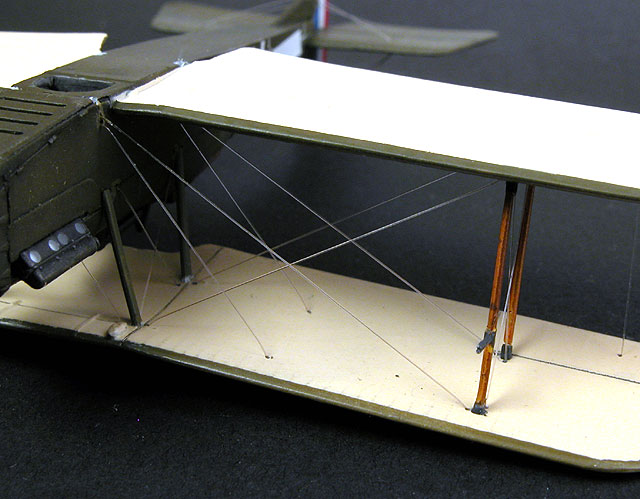

I started by drilling holes to thread the rigging before painting or

gluing the top wing, and before painting the top surface of the lower

wing. I also did not add the undercarriage until I had finished the main

rigging.

This is because I drill the holes all the way through the wing. I have

found that it is easier to rig the model, then clean up, fill the holes

and paint the wings after rigging.

My thread of choice is monofilament (nylon invisible mending thread) as

it is very strong and looks reasonably to scale. With care, it can be

tightened by applying heat similar to the method used with stretched

sprue.

Before starting the rigging, take care that the glue on the top wing and

struts is completely set. Also, do not use too much weight when

stretching the rigging or it might pull the wings out of alignment or,

worse, break the bond of the struts.

I cut a piece of thread about double the length I need and thread it

through both holes. I then touch some slow-setting super glue on a

toothpick to the outside surface of the top wing where the thread is

exposed. When this has dried, I take the other end exposed at the bottom

of the lower wing, add a small weight for tension, and repeat the gluing

process.

It is preferable to start rigging from inboard-out, and to work on both

sides of the model progressively. For example, when you have finished

the farthest inboard wire on the port side, start working on the

equivalent starboard side wire next.

Once the initial rigging is completed, the excess thread exposed from

the top and bottom of the wings may be sliced off with a sharp scalpel.

For rigging that enters the fuselage, I usually start with the fuselage

end of the thread, adding a drop of super glue and poking it into the

hole.

When the rigging is complete, the remainder of the wings can be painted,

followed by the adding of the undercarriage. Remember that most biplanes

had some sort of rigging on the undercarriage. This area can have the

same treatment as the wings, but donít forget to let the plastic glue

harden for around 24 hours before rigging here too.

I am not suggesting that this is the best or easiest method for

rigging a biplane but, with care and time, a good result can be

achieved.

If you talk to other biplane modellers they may have alternate methods

that you prefer. Either way, have a crack at rigging your next biplane.

It does make a big difference to the final appearance of your WWI

biplane!

Model and Text Copyright © 2003 by Glen Porter

Images Copyright © 2003 by

Brett Green

Page Created 02 June, 2003

Last Updated 02 June, 2003

Back to HyperScale

Main Page

|

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search